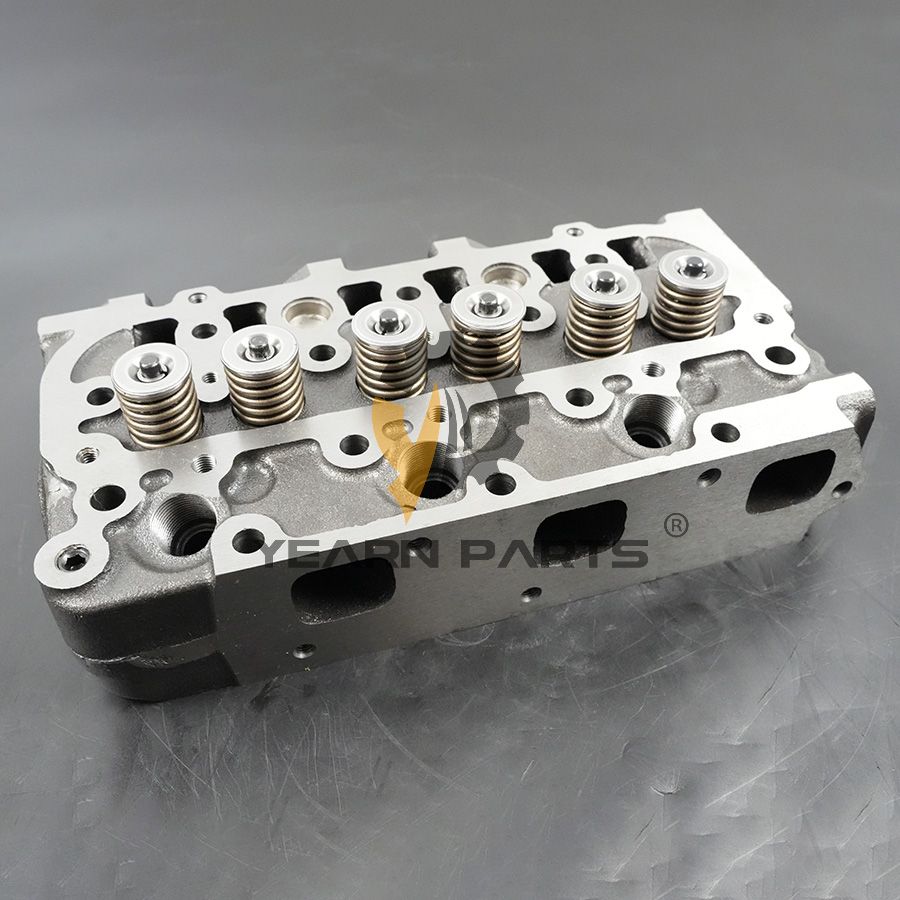

Resource Precision-engineered Bobcat Aftermarket Parts for Boosted Performance

Resource Precision-engineered Bobcat Aftermarket Parts for Boosted Performance

Blog Article

Reviewing the Advantages of Aftermarket Parts in the Maintenance of Machinery and Heavy Equipment

In the realm of equipment and heavy tools maintenance, the discussion surrounding using aftermarket components is one that stimulates inquisitiveness and prompts a better assessment. As specialists entrusted with making certain optimal efficiency and durability of machinery, it comes to be vital to check out the advantages that aftermarket parts provide. From cost-effectiveness to personalization options customized to certain demands, these components provide an engaging situation for factor to consider in the upkeep landscape. Allow's dig deeper into the realm of aftermarket components and reveal the benefits that make them a viable selection for sectors reliant on effective machinery procedure.

Cost-Effectiveness of Aftermarket Components

Utilizing aftermarket components for equipment upkeep has been shown to considerably enhance cost-effectiveness without endangering high quality or efficiency. These components, which are created by third-party manufacturers as choices to original tools producer (OEM) components, provide different benefits in regards to affordability and availability. Aftermarket components are generally priced less than their OEM equivalents, making them an extra budget-friendly alternative for companies aiming to lower upkeep expenses without giving up reliability.

One crucial element adding to the cost-effectiveness of aftermarket components is the open market they exist in. With multiple manufacturers creating these parts, rates ends up being extra competitive, eventually profiting the consumer. Moreover, the availability of aftermarket parts is typically higher contrasted to OEM parts, as they can be sourced from a selection of suppliers and suppliers. This availability not just decreases preparations for repair work yet additionally offers adaptability in choosing the best-priced option without jeopardizing on high quality.

Wide Accessibility and Ease Of Access

Aftermarket parts, known for their cost-effectiveness in equipment maintenance, show significant advantages through their vast accessibility and availability in the marketplace. Unlike OEM (Original Tools Producer) parts that may be restricted to particular car dealerships or suppliers, aftermarket components are widely produced by various third-party makers (Bobcat Aftermarket Parts). This extensive manufacturing brings about a broad distribution network, making aftermarket parts quickly accessible to consumers throughout different areas

Comparable Top Quality to OEM Parts

With innovations in making processes and quality control requirements, aftermarket parts currently use a degree of top quality that is similar to OEM parts. In the past, there was an usual misunderstanding that aftermarket components were of substandard top quality compared to initial equipment producer (OEM) parts. Due to technical progression and boosted competitors in the aftermarket sector, several aftermarket suppliers have actually considerably boosted their manufacturing procedures and products to satisfy or also surpass the top quality criteria established by OEMs.

One of the main reasons aftermarket components currently measure up to OEM components in quality is the extensive screening and certification procedures that numerous published here aftermarket makers abide by. These firms understand the relevance of producing premium parts that can perform reliably in numerous equipment and tools. Because of this, customers can currently confidently select aftermarket components understanding that they use similar quality to OEM components at an extra budget friendly rate factor.

Personalization Options for Particular Requirements

For equipment upkeep, aftermarket components use a series of customization choices customized to certain demands, allowing organizations to maximize their tools efficiency effectively. Modification is an essential advantage of aftermarket components as it allows firms to adapt parts to satisfy distinct requirements that may not be addressed by conventional OEM parts. Whether it's customizing materials, dimensions, or attributes, aftermarket vendors commonly offer the adaptability needed to enhance equipment efficiency in specialized applications. When devices is used in non-conventional methods., this modification capacity is particularly useful in sectors with distinctive functional needs or.

Furthermore, aftermarket components distributors can function very closely with companies to comprehend their details difficulties and style parts that attend to these problems efficiently. Bobcat Aftermarket Parts. This tailored approach to customization can result in enhanced equipment capability, boosted productivity, and decreased downtime due to tailored remedies that align with the business's operational objectives. By leveraging aftermarket components with customization options, companies can maximize their equipment to do at its ideal, inevitably leading to boosted total functional performance and cost-effectiveness

Swift Shipment and Minimized Downtime

Provided the tailored options given by aftermarket components for specific i was reading this machinery demands, companies can gain from speedy delivery and reduced downtime through efficient supply chain monitoring methods. Time is important in the commercial sector, where any type of equipment downtime can cause considerable economic losses. Aftermarket components suppliers understand this seriousness and often stand out in giving fast shipment options to reduce tools idle time. By partnering with dependable aftermarket components providers, organizations can access a wide variety of products promptly, making certain that repair and maintenance are accomplished promptly to get machinery back up and running.

Minimized downtime is vital for preserving efficiency degrees and conference job due dates. By having access to a diverse supply of aftermarket parts that can be delivered immediately, organizations can stay clear of prolonged periods of devices lack of exercise. This performance in supply chain monitoring not only conserves time but likewise adds to cost savings by lowering the impact of downtime on overall operations. To conclude, the quick shipment of aftermarket components plays an essential role in minimizing downtime, enhancing operational performance, and ultimately making sure the seamless performance of equipment and heavy devices.

Final Thought

Unlike OEM (Original Equipment Manufacturer) parts that might be restricted to particular dealers or producers, aftermarket parts are extensively generated by different third-party makers (Bobcat Aftermarket Parts). Furthermore, the competitive market for aftermarket components usually results in reduced costs and promos, permitting clients to obtain quality parts at a lowered expense compared to OEM components

With improvements in producing processes and top quality control requirements, aftermarket parts currently provide a degree of high quality that is comparable to OEM components. In the past, there was a common false impression that aftermarket parts were of inferior top quality contrasted to original tools maker (OEM) parts.One of the major factors aftermarket components currently match OEM components in top quality is the extensive testing and qualification procedures that lots of aftermarket producers stick to.

Report this page